Rubber seals are critical components in modern architectural facade systems, providing crucial sealing, insulation, and structural protection. They play a key role in enhancing facade durability, performance, and energy efficiency.

Table of Contents

Classification of Rubber Seals

EPDM Rubber Seals

EPDM seals are widely used due to their superior weather resistance, UV stability, and durability, ideal for outdoor architectural applications. Silicone Rubber Seals

Silicone seals excel in extreme temperature ranges (-60°C to +230°C) and offer excellent flexibility and long-term elasticity, making them suitable for advanced facade designs.

Neoprene Rubber Seals

Known for chemical and abrasion resistance, neoprene seals are preferred in environments that demand enhanced chemical protection.

Thermoplastic Elastomers (TPE) Seals

TPE seals combine elasticity and durability, providing cost-effective sealing solutions adaptable to complex facade geometries.

PVC Seals

PVC rubber seals offer economical solutions with good weather resistance and ease of processing, ideal for general facade applications.

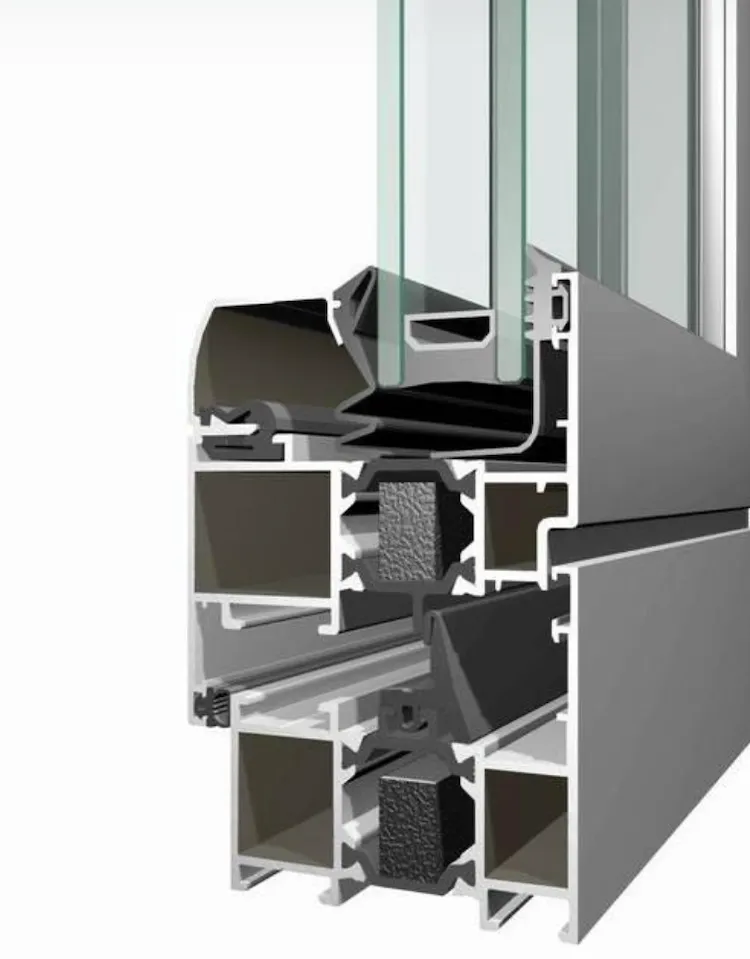

Common Facade Systems Utilizing Rubber Seals

Curtain Wall Facade Systems

Rubber seals provide critical weatherproofing and thermal insulation, ensuring high-performance curtain walls.

Window and Door Systems

High-quality seals ensure windows and doors maintain their thermal and acoustic performance over time.

Glass Facades

Rubber seals secure glass panels, preventing water ingress and enhancing facade durability.

Metal Cladding Systems

Specialized rubber seals prevent corrosion and secure metal cladding effectively against weather elements.

Ventilated Facade Systems

Rubber seals in ventilated facades ensure ventilation efficiency without compromising waterproofing.

Main Purposes of Rubber Seals in Architectural Facades

Weatherproofing and Water Resistance

Prevents moisture infiltration, protecting facade integrity.

Thermal Insulation and Energy Efficiency

Reduces heat loss, enhancing energy savings and comfort.

Acoustic Insulation and Noise Reduction

Improves building acoustics, minimizing external noise.

Dust and Air Leakage Prevention

Maintains air quality and prevents contamination within interiors.

Enhancing Structural Integrity and Safety

Supports facade durability against environmental impacts and structural stress.

Material Properties and Performance

Material Composition and Durability

Quality rubbers ensure extended lifespan and minimal maintenance.

Hardness and Flexibility (Shore Hardness Scale)

Customizable hardness levels from 30 to 95 Shore A to meet specific facade requirements.

Temperature and UV Resistance

High resistance to UV rays and extreme temperatures protects facade longevity.

Chemical and Corrosion Resistance

Protects facades in chemically aggressive environments.

Manufacturing Processes of Rubber Seals

Extrusion Process and Applications

Ideal for continuous lengths, ensuring uniformity and quality.

Injection Molding Technique

Preferred for precision in complex seal designs.

Compression Molding and its Benefits

Suitable for high-strength seals and enhanced performance requirements.

Vulcanization and Surface Treatments

Improves rubber strength, elasticity, and surface integrity.

Post-Processing and Finishing Methods

Ensures accurate dimensions and excellent final product quality.

Customization Services for Architectural Rubber Seals

Custom Dimensions and Geometries

Tailored precisely to meet architectural requirements.

Color Matching and Options

Seals available in multiple color choices to match facade aesthetics.

Custom Hardness Specifications

Customized hardness levels to suit specific structural and installation requirements.

Tailored Solutions for Special Projects

Fully customized sealing solutions designed for unique facade projects.

Quality Standards and Certifications

ASTM Standards Compliance

Ensures products meet international quality benchmarks.

ISO Certification and Importance

Guarantees consistent product quality and reliability.

Fire Safety Ratings and Testing

Compliance with critical fire safety standards.

Environmental and Sustainability Certifications

Supports sustainable building practices and environmental standards.

Pricing Factors for Custom Rubber Seals

Influence of Material Type on Pricing

Prices typically range from $0.50 to $5.00 per meter, depending on the rubber type.

Impact of Seal Customization and Complexity

Complex designs and specifications significantly influence pricing.

Production Quantity and Pricing Strategies

Economies of scale achieved through bulk orders reduce unit costs.

Estimating Lead Times and Cost Management

Typical lead times range from 2 to 6 weeks, based on customization levels.

Typical Project Applications and Case Studies

Commercial Building Facade Projects

Examples of high-performance facade sealing solutions.

Residential and Apartment Complexes

Case studies highlighting residential sealing efficiency.

Industrial Facility Applications

Specialized sealing solutions addressing industrial challenges.

Institutional and Public Building Examples

Ensuring long-term performance and public safety through high-quality sealing.

Choosing the Right Rubber Seal for Your Facade

Selecting appropriate rubber seals is vital for facade performance, longevity, and aesthetic appeal. Partner with Albang Hardware for custom rubber seals tailored to your architectural project needs.

Contact Albang Hardware today to discuss your custom facade sealing solutions and receive a personalized quote tailored specifically to your project requirements.