Albang Hardware offers complimentary high/low-temperature testing (100+ hours at 100°C and -40°C) for all custom seal orders, ensuring product reliability under extreme conditions. This quality assurance initiative underscores our commitment to durability and customer confidence, allowing clients to trust Albang Hardware’s seals for mission-critical applications.

1. Purpose of the Test

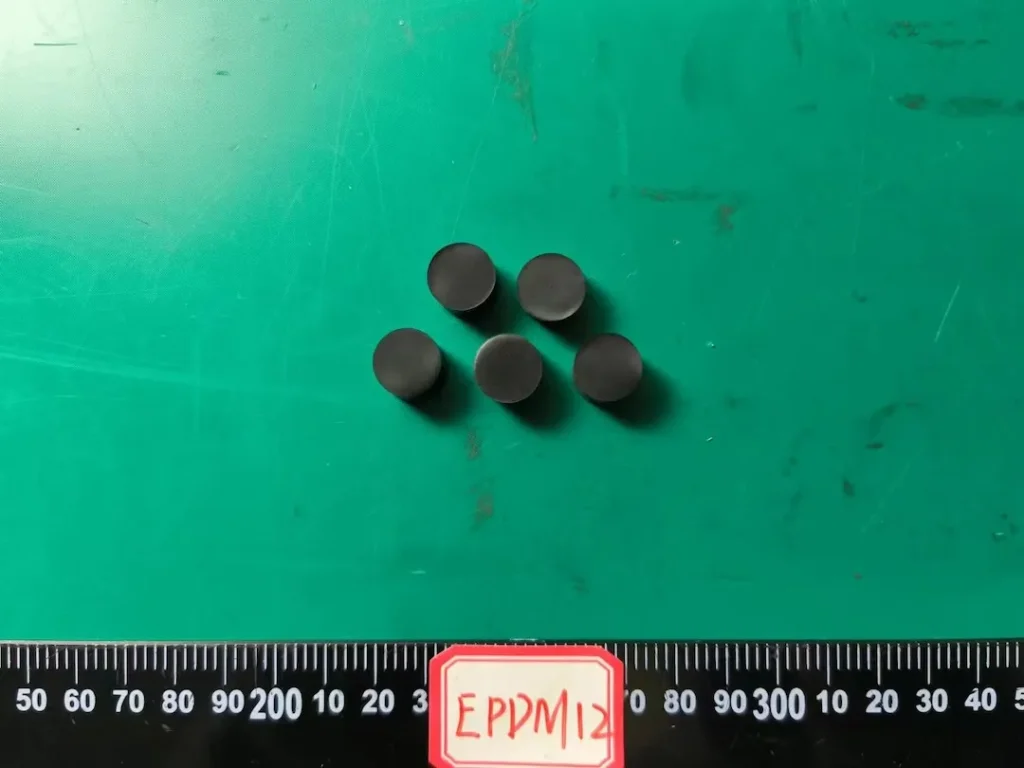

This report evaluates the performance of rubber sealing strips under high and low-temperature conditions, focusing on changes in Shore hardness. These changes reflect the material’s ability to maintain stability, flexibility, and sealing performance in extreme environments.

2. Shore Hardness Test Method

Equipment:

- Shore A hardness tester: Suitable for soft rubber materials such as EPDM and silicone.

Testing Procedure:

- Place the sample on a flat, level surface.

- Press the indenter of the Shore A hardness tester vertically onto the sample.

- Record the penetration depth after 3 seconds and calculate the hardness.

- Shallower penetration = Higher hardness.

- Deeper penetration = Lower hardness.

Testing Standards:

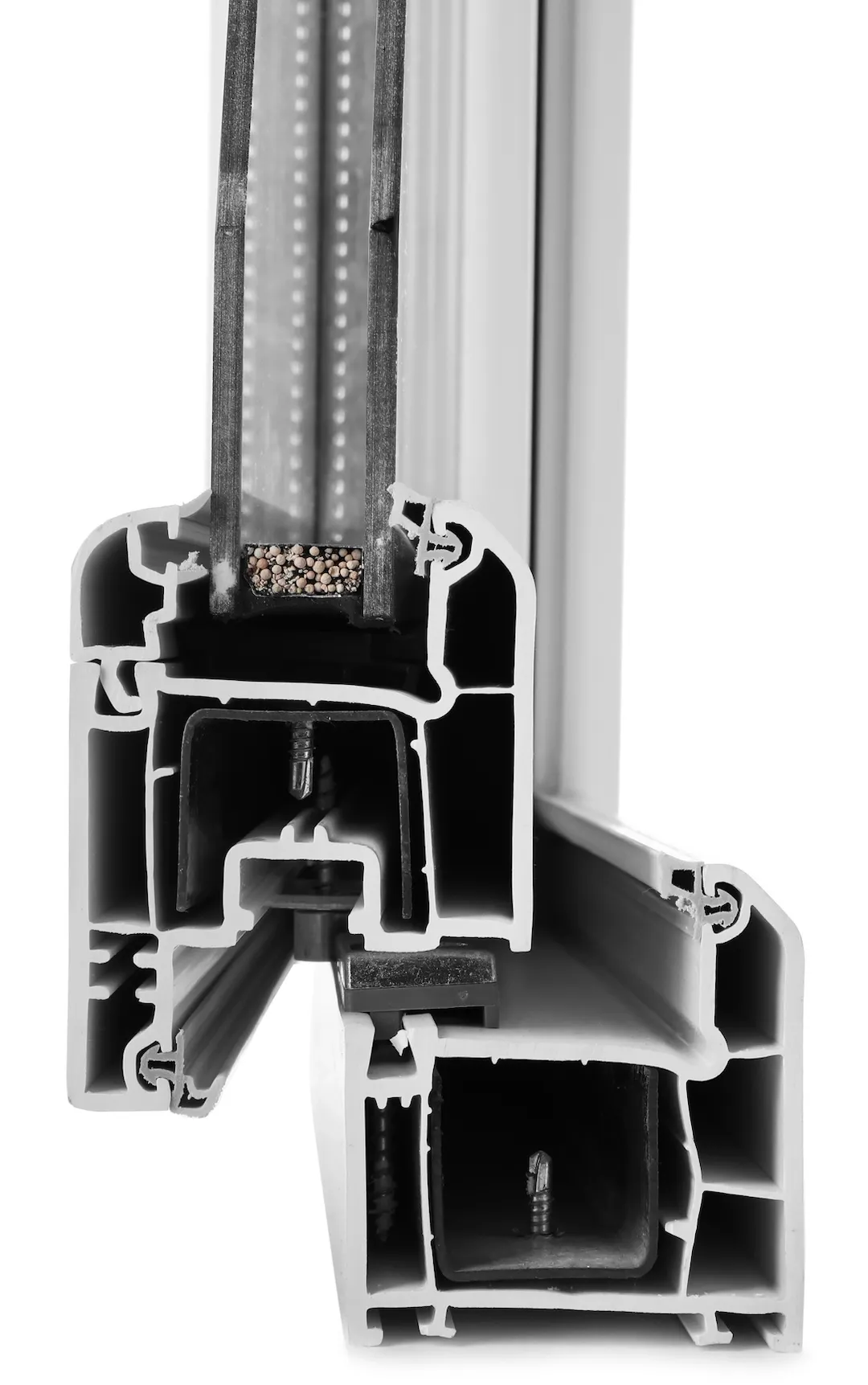

The procedure follows the guidelines of GB/T 24498-2009 for sealing strips used in building doors, windows, and curtain walls.

3. High and Low-Temperature Test Results

Testing Conditions:

- High Temperature: Samples were conditioned at 100°C for 100 hours before testing.

- Low Temperature: Samples were conditioned at -40°C for 100 hours before testing.

Test Results:

| Condition | Initial Shore Hardness | Post-Test Shore Hardness | Change |

|---|---|---|---|

| High Temperature | 65 | 70 | ±5-10 |

| Low Temperature | 60 | 70 | ±5-10 |

4. Analysis of Results

The hardness variation under high and low-temperature conditions was minimal, with a maximum change of ±3 Shore A units. This indicates the following:

- Excellent Thermal Stability:

- The material resists softening at high temperatures, maintaining mechanical properties and sealing performance.

- Good Low-Temperature Flexibility:

- The material remains flexible without becoming brittle in cold conditions, ensuring reliable sealing.

- Superior Material Quality:

- The small variation in hardness demonstrates the use of high-quality materials and precise formulations, ensuring reliability and durability under extreme conditions.

5. Conclusion

The test results confirm that the rubber sealing strips produced by Albang Hardware meet strict quality standards. Their ability to maintain consistent hardness under high and low-temperature conditions highlights the following advantages:

- Reliable sealing performance across varying environmental conditions.

- Long-term durability with no significant degradation.

- Exceptional material quality, suitable for applications in extreme climates.

Albang Hardware‘s products are highly suitable for demanding applications, including building doors, windows, and curtain wall systems. This test reaffirms their commitment to providing high-performance solutions.