Albang Hardware, a professional glass facade spider systems manufacturer in China, offers comprehensive solutions designed to meet the modern architectural demands for transparency, minimal framing, and structural integrity.

Table of Contents

Classification of Glass Facade Spider Systems

By Fitting Type

Glass facade spider systems primarily feature traditional Spider Fittings and the innovative Point Supported Hook Systems, each catering to unique design requirements.

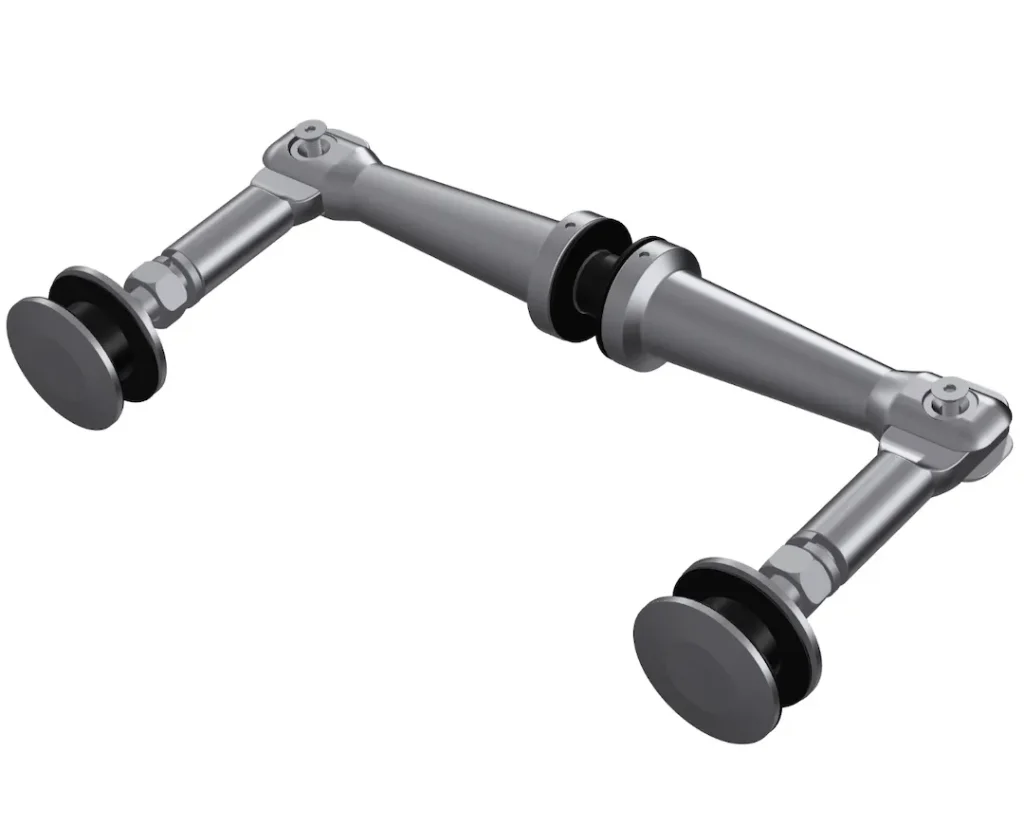

By Arm Configuration

Systems vary from single-arm configurations for minimal support to quadruple-arm configurations offering enhanced stability. The popular Double Arm spider fittings come in multiple angles (180°, 90°, 135°) for versatile layout options.

Components of a Glass Facade Spider System

Spider Fittings

Spider fittings are the main connecting elements holding glass panels securely in place, available in various designs tailored to structural and aesthetic needs.

glass facade spider VP202

glass facade spider VP201

glass facade spider L300A

glass facade spider L300E

glass facade spider L300F

Routels and Glass Connectors

Routels connect the glass to spider fittings, with Fixed Routels providing rigidity and Articulated Routels allowing slight movement for dynamic structures.

Bolts and Attachment Hardware

Attachment hardware includes Countersunk, Flat Head, and Dome Head bolts, chosen based on visual and functional requirements.

Structural Support Elements

Structural supports, including glass fins, steel mullions, and tension rod systems, ensure optimal load distribution and facade stability.

Introduction to Point-Supported Hook System

What is the Hook System?

The Hook System offers a sleek alternative to traditional spider systems, utilizing a simple yet innovative design.

Features of the Hook System

Allowing rotation around the pin axis and horizontal movement, the Hook System accommodates standard glass thicknesses (10-26mm) and employs corrosion-resistant 316 stainless steel.

Material Options for Spider Systems

Stainless Steel 304

Economical and suitable for standard environments, Stainless Steel 304 offers good strength and moderate corrosion resistance.

Stainless Steel 316

Ideal for coastal or aggressive environments, Stainless Steel 316 provides superior corrosion resistance.

Duplex Stainless Steel

For high load or extreme conditions, Duplex Stainless Steel ensures enhanced structural strength and durability.

Surface Finishing Options

Mirror Polished

A premium reflective finish enhancing aesthetic appeal.

Satin Brushed

Provides a modern, elegant appearance with minimal reflection.

PVD Coating

Available in various colors like black, gold, and bronze, offering enhanced aesthetics and durability.

Electropolished

Recommended for marine environments, this finish enhances corrosion resistance.

Purpose and Advantages of Spider Systems

Frameless Aesthetic

Creates visually appealing, modern architecture by minimizing visible structures.

Structural Efficiency

Efficiently distributes loads, suitable for various seismic conditions and dynamic environments.

Design Flexibility

Adaptable to flat, curved, and inclined facade configurations.

Manufacturing Process of Spider Fittings

Raw Material Selection

Premium-grade stainless steel materials undergo rigorous quality testing to ensure structural integrity.

Precision Casting and CNC Machining

Advanced casting techniques combined with CNC machining deliver precise and durable components.

Surface Treatment and Finishing

Components undergo meticulous surface finishing, including polishing, brushing, or PVD coating.

Assembly and Quality Inspection

Final assemblies are rigorously inspected for strength, corrosion resistance, and aesthetic quality.

Cost and Pricing of Glass Facade Spider Systems

Factors Affecting Price

Key factors include material selection, system type, glass specifications, load-bearing capacities, and customization complexity.

Typical Price Range

Albang Hardware offers competitive pricing across entry-level systems to highly customized, premium solutions.

Customization Services

Custom Arm Lengths and Geometries

Customized arm configurations tailored to unique facade designs.

Surface Color and Finish Customization

Matching specific architectural themes with customized colors and finishes.

Special Load Requirements

Adjustments available for enhanced seismic resilience and wind load management.

Branding and Engraving Options

Custom logo engraving available for personalized project branding.

Applications of Glass Facade Spider Systems

Commercial Projects

Widely utilized in commercial buildings, office towers, airports, and shopping malls.

Public Spaces

Ideal for museums, exhibition centers, and visually impressive structures like glass bridges.

Canopies and Skylights

Perfect for transparent roofing systems, allowing natural lighting while ensuring structural safety.

Installation Methods

Wall-Mounted Installations

Direct installation onto structural walls or framing.

Fin-Supported Systems

Utilize vertical glass fins to distribute loads efficiently.

Tension Cable Supported Systems

Optimized for lightweight, expansive facade designs.

Hook Supported Systems

Allow simplified installation and maintenance with easy panel replacement.

Conclusion

Glass facade spider systems continue to shape contemporary architectural design, blending aesthetics with robust engineering solutions. Albang Hardware ensures top-quality products customized to your architectural vision.

Contact Albang Hardware today to discuss your project needs and receive expert consultation and competitive quotes tailored specifically for you.