Albang Hardware produces essential components that enhance the energy efficiency, weatherproofing, and sound insulation of buildings. Albang Hardware is involved in designing, producing, and supplying rubber seal strips used for sealing gaps around doors and windows. These strips are crucial for preventing drafts, water ingress, and noise pollution, thereby improving the overall comfort and energy efficiency of residential and commercial spaces. The production process at Albang Hardware involves selecting appropriate materials, such as EPDM, silicone, or PVC, to ensure durability and performance under various environmental conditions. Albang Hardware often offers customization options to fit different door and window profiles and may provide additional services such as installation guidance or technical support.

Table of Contents

Classification of Rubber Seal Strips

Weatherproofing and Environmental Resistance

- Air leakage prevention, UV stability, waterproofing, ozone resistance, weather resistance testing

Energy Efficiency and Thermal Insulation

- Heat retention, cold air exclusion, temperature regulation, building energy performance, thermal barriers

Soundproofing and Acoustic Solutions

- Noise reduction, vibration damping, office/residential soundproofing, quiet environments, acoustic insulation

Product Models and Specifications

EPDM Rubber Seals

- Temperature resistance, long-lasting performance, environmental resistance, flexibility, aging resistance

Silicone Seal Strips

- Heat/cold resistance, non-toxic material, food-grade applications, chemical resistance, hygienic seals

PVC Sealing Strips

- Cost-effective, lightweight, moisture barrier, color options, aesthetic enhancement, anti-dust properties

Purpose and Application Areas

Residential Use

- Door draft prevention, window leak prevention, enhanced comfort, noise control, thermal insulation

Commercial and Industrial Use

- Bulk production, industrial applications, HVAC sealing, machinery enclosures, precision gaskets

Specialized Solutions

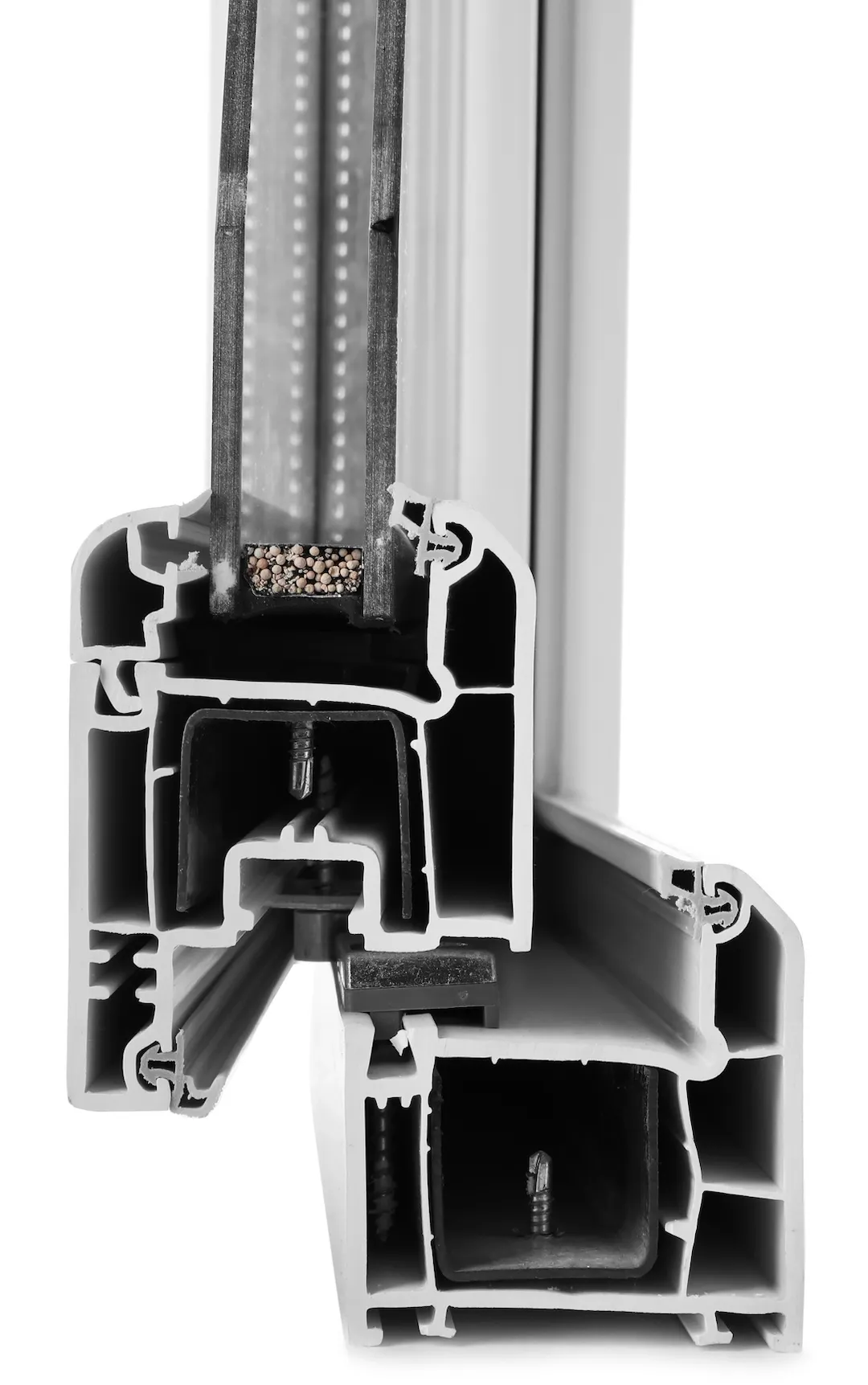

- Double glazing seals, automotive gaskets, airtight windows, rubber-to-metal bonding, high-temperature applications

Manufacturing Process and Techniques

Extruded Seals Production

- Custom extrusions, profile design, continuous manufacturing, extrusion technology, flexible profiles

Adhesive Integration

- Self-adhesive strips, peel-and-stick solutions, permanent adhesion, removable adhesives, bonding strength

Industrial Manufacturing Standards

- Precision tooling, material expertise, OEM services, ISO-certified processes, technical support

Quality Control (QC) at Albang Hardware

Raw Material Inspection

- Supplier audits, EPDM/silicone/PVC material certification, UV/ozone resistance testing, compliance with RoHS/REACH standards

In-Process Quality Checks

- Dimensional accuracy verification, extrusion profile consistency, adhesive bonding strength tests, defect detection systems

Final Product Testing

- Air/water leakage simulations, thermal cycling tests, acoustic performance validation, durability under extreme conditions

Certifications and Compliance

- ISO 9001/14001 certifications, fire safety standards (UL94/EN 13501), food-grade silicone compliance (FDA), environmental regulations

Unit Price and Cost Considerations

Economy-Grade Seals (PVC/Foam)

- $0.25–$1.00 per meter: Budget-friendly, ideal for residential draft exclusion and basic insulation

Mid-Range Seals (EPDM/Silicone)

- $1.00–$3.00 per meter: Commercial durability, thermal/acoustic performance, UV/chemical resistance

Premium and Custom Solutions

- $2.00–$6.00+ per meter: Industrial-grade extrusions, fireproof materials, food-grade silicone, bespoke designs

Customization Services

Tailored Seal Designs

- Custom gaskets, unique door/window profiles, adjustable seals, rubber-to-metal bonding, extrusion design

Adhesive Solutions

- Adhesive-backed strips, installation tools, permanent/removable options, bonding for complex surfaces

Industrial and OEM Support

- Bulk production, specialized seals, precision manufacturing, technical guidance, quality certifications

Specialized Features and Innovations

Hygienic and Non-Toxic Seals

- Food-grade silicone, anti-microbial properties, non-toxic materials, hygienic applications

High-Performance Weatherseals

- Weatherproof designs, longevity testing, environmental protection, reinforced edges, leak-proof barriers

Advanced Soundproofing Technology

- Decibel-reducing strips, vibration dampening, office/residential noise control, acoustic barriers