Table of Contents

Introduction to Countersunk Head Glass Fixing Bolts

Albang Hardware is a professional Countersunk Head Glass Fixing Bolts for Frameless Facades manufacturer in China. We specialize in providing high-quality, precision-engineered glass bolts tailored to meet the stringent demands of modern architectural projects.

What are Countersunk Head Glass Bolts?

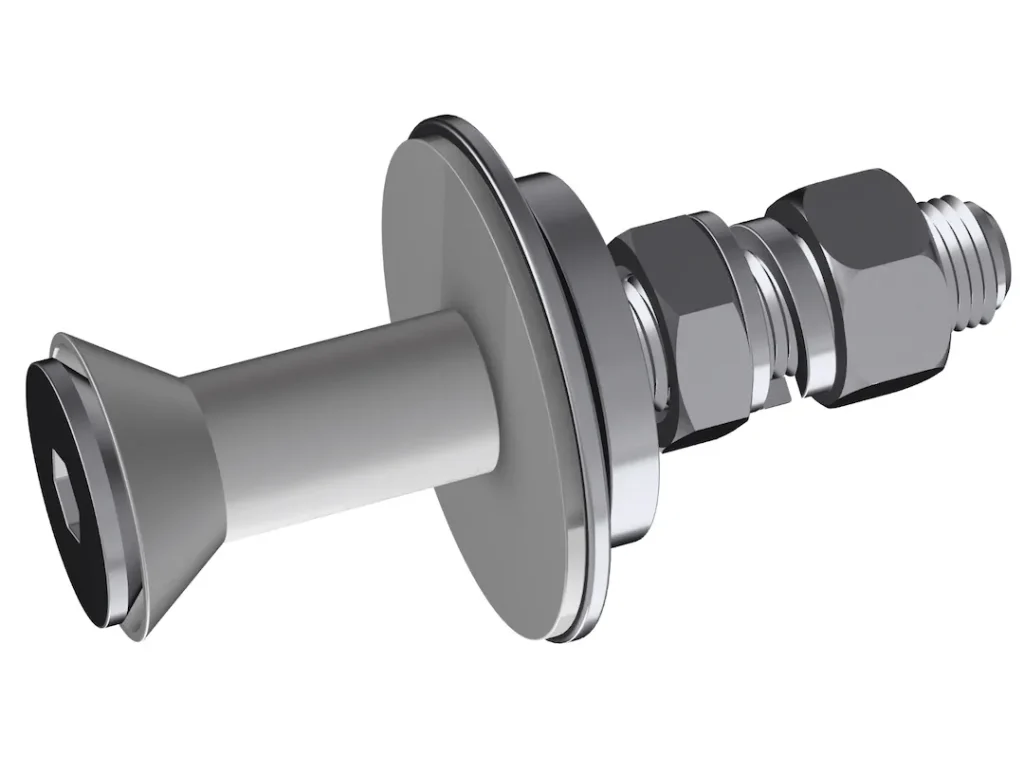

Countersunk Head Glass Bolts are specialized fasteners designed with a flat, conical head that sits flush with the glass surface, providing a seamless and aesthetically appealing finish. These bolts are extensively used in structural glazing systems, offering robust and secure glass panel fixation.

Importance of Structural Glazing Systems

These bolts are crucial in structural glazing systems, ensuring structural integrity, safety, and aesthetic harmony. They securely fasten glass panels without compromising visual clarity or architectural elegance.

Key Advantages of Using Countersunk Head Bolts

- Seamless flush installation

- Enhanced aesthetic appeal

- Improved safety and structural strength

- Reduced risk of glass damage

Classification of Countersunk Head Glass Fixing Bolts

By Material

- Stainless Steel (304, 316): Offers superior corrosion resistance and strength.

- Aluminium Alloy Bolts: Lightweight alternative for specific applications.

By Surface Finish

- Mirror Polished Bolts: Reflective, high-gloss finish ideal for premium aesthetics.

- Satin (Brushed) Finish Bolts: Subtle, modern matte appearance.

- PVD-Coated Finish Bolts: Enhanced durability with decorative color options.

By Application

- Curtain Wall Fixing Bolts: Ensures structural integrity in large-scale glazing projects.

- Canopy Glass Bolts: Secure, weather-resistant solutions for glass canopies.

- Balustrade & Railing Bolts: Reliable fastening for safety-critical railing systems.

Main Models & Specifications

Standard Dimensions & Sizes

Common sizes range from M8 to M12 with lengths varying from 30mm to 100mm, customizable per project requirements.

Countersunk Head Angles (e.g., 90°)

Typically standardized at 90°, customizable angles are available upon request.

Load Capacity and Performance Standards

Designed to withstand significant loads (50-100 kg per bolt), complying with international safety standards.

Suitable Glass Thickness Range

Compatible with glass thicknesses ranging from 6mm to 25mm or customized specifications.

Manufacturing Process & Quality Control

Raw Material Selection & Inspection

Only premium-grade stainless steel or certified aluminium alloys are selected and rigorously inspected.

Machining & Countersinking Process

Precision CNC machining ensures exact dimensions, flawless countersunk profiles, and consistency across batches.

Surface Treatment and Finishing Methods

Advanced surface treatments, including polishing, brushing, and PVD coating, provide optimal protection and aesthetics.

Quality Control and Certification Standards

Our bolts undergo strict quality checks and comply with ISO 9001 standards and international glazing safety regulations.

Typical Applications & Installation Methods

Application in Glass Curtain Walls

Provides seamless, secure installations suitable for high-rise and commercial building facades.

Application in Glass Canopies

Robust solution for outdoor installations, ensuring weather resistance and long-term performance.

Application in Frameless Balustrades & Railings

Safety-focused fastening method maintains sleek and modern aesthetics in glass railings.

Recommended Installation Procedures & Tips

Use calibrated tools to ensure correct torque and alignment. Regular inspections during installation guarantee long-term reliability.

Cost and Price Factors

Pricing by Material Grade

Stainless steel variants generally command premium pricing compared to aluminium options.

Influence of Surface Finish on Cost

Specialized finishes like mirror polish or PVD coatings can slightly increase the overall cost.

Bulk Order Pricing and Wholesale Discounts

Attractive pricing structures are available for bulk orders, OEM projects, and regular wholesale clients.

Customization Services Available

OEM & Customized Dimensions

We offer complete customization, including special dimensions, head angles, and bespoke engineering designs.

Custom Surface Finishing Options

Tailored finishing solutions are available to meet unique aesthetic or functional requirements.

Tailored Solutions for Special Glass Thicknesses

Custom-engineered bolts are specifically designed for unique glass thicknesses and special structural requirements.

Branding and Private Labeling Services

OEM and private labeling services are available, ensuring your brand’s visibility and recognition.

Frequently Asked Questions (FAQs)

How to Choose the Right Countersunk Glass Bolt?

Select based on project specifications, glass thickness, load capacity requirements, and environmental conditions.

What Glass Thickness is Compatible?

Our bolts generally suit glass thicknesses between 6mm and 25mm; custom solutions are also available.

Are Countersunk Bolts Adjustable After Installation?

Limited adjustments are possible; accurate pre-installation measurement and alignment are recommended.

How to Order Custom-made Countersunk Glass Bolts?

Contact our sales team with your specifications, drawings, or requirements for a prompt quotation.

What is the Lead Time for Bulk Orders?

Standard lead time is typically 15-30 days, with expedited services available upon request.

Conclusion and Recommendations

Why Choose Countersunk Head Bolts for Your Project

Countersunk Head Glass Fixing Bolts from Albang Hardware ensure premium aesthetics, unmatched structural integrity, and customized solutions tailored to your architectural needs.

Next Steps for Ordering or Getting a Quote

Reach out to Albang Hardware for professional consultation, quotations, or technical support to optimize your next glass facade project.