Albang Hardware specializes in the production of rubber sealing solutions used in various architectural applications. Albang Hardware designs and manufactures seals that are essential for maintaining the integrity and performance of buildings, ensuring water resistance, air tightness, and energy efficiency. The company caters to a wide range of architectural needs, including window seals, door seals, and innovative building envelope solutions. Albang Hardware’s seals are engineered from durable, weather-resistant materials such as EPDM, silicone, and fluorocarbon rubber, capable of withstanding extreme temperatures (-60°C to +250°C), UV exposure, and chemical stresses. These solutions directly contribute to structural longevity, with certified fire-rated seals offering up to 4 hours of fire resistance (GB 23864 compliance) and acoustic seals achieving 30+ dB noise reduction (ASTM E90 standards). By integrating advanced extrusion and molding technologies, Albang Hardware delivers customized profiles that meet LEED and BREEAM sustainability requirements, reducing building energy consumption by 15–20% through optimized thermal breaks and airtight sealing systems.

Table of Contents

Classification System

By Base Material Type

- Rubber-Based: Sulfur-modified rubber, silicone rubber, EPDM (elasticity & weather resistance);

- Resin-Based: Epoxy, polyurethane (high-strength bonding);

- Oil-Based: Natural/vegetable oils (low-intensity sealing).

By Curing Method

- Moisture Curing: Environment-dependent (e.g., silicone rubber);

- Chemical Curing: Two-component systems (e.g., polyurethane);

- Heat-Activated Curing: Thermoplastic blends (e.g., PVC-rubber hybrids).

By Functional Properties

- Temperature Resistance: Silicone (-60°C–230°C), fluorocarbon rubber (-20°C–250°C);

- Chemical/Oil Resistance: Fluorocarbon rubber (oil resistance), EPDM (acid/alkali tolerance);

- Dynamic/Static Sealing: High abrasion resistance for dynamic use (e.g., rotating machinery), compression recovery for static applications.

By Structural Design

- O-Rings: Universal for low-speed dynamic/static seals;

- Extruded Profiles: Window/door seals, curtain wall joints;

- Custom Composite Designs: Fire-rated expanding seals.

Material Properties & Selection

EPDM (Ethylene Propylene Diene Monomer)

- Advantages: UV/ozone resistance, cost-effective;

- Limitations: Poor oil resistance, max. 130°C;

- Applications: Window/door seals, roofing.

Silicone Rubber

- Advantages: High-temperature stability (230°C+), food-grade safety;

- Limitations: Low mechanical strength, high cost;

- Applications: Medical devices, high-temperature seals.

Fluorocarbon Rubber (FKM)

- Advantages: Oil/chemical resistance, flame retardancy;

- Limitations: Brittle below -20°C;

- Applications: Chemical pipelines, automotive fuel systems.

Material Comparison Matrix

| Property | EPDM | Silicone | FKM |

|---|---|---|---|

| Temp. Range | -40–130°C | -60–230°C | -20–250°C |

| Oil Resistance | Poor | Moderate | Excellent |

| Cost | Low | High | High |

| Key Applications | Building | Medical | Industrial |

Manufacturing Processes

Key Production Methods

- Extrusion: For continuous profiles (e.g., window/door seals) using screw extruders;

- Compression Molding: For complex geometries (e.g., O-rings) with hydraulic presses;

- Injection Molding: High-precision seals (e.g., automotive components) using rubber injection machines.

Process Steps

- Material Mixing: Rubber compounds blended with additives (e.g., carbon black, plasticizers).

- Performing: Shaping uncured rubber into blanks or pellets.

- Curing: Vulcanization in autoclaves or heated molds to crosslink polymers.

- Post-processing: Trimming, surface coating (e.g., silicone spray), or adhesion treatments.

Equipment

- Extruders with crosshead dies for profile shaping;

- Vulcanization ovens (150–200°C for EPDM);

- CNC cutting machines for precision trimming.

Quality Control & Testing

Physical Performance Tests

- Tensile Strength: ASTM D412 (measuring elongation and break resistance);

- Hardness: Shore A durometer per ASTM D2240;

- Compression Set: ASTM D395 (evaluating recovery after deformation).

Environmental Resistance Tests

- Weathering: QUV accelerated aging (UV exposure per ASTM G154);

- Chemical Immersion: ASTM D471 (measuring volume/swell changes in oils/acids);

- Thermal Cycling: Alternating between -40°C and 100°C (ISO 3384).

Functional Validation

- Air/Water Tightness: Chamber tests with pressure differentials (e.g., 1500 Pa for windows);

- Fire Resistance: Furnace tests (e.g., EN 1366-4 for fire-rated seals);

- Acoustic Performance: Sound transmission loss (ASTM E90).

Certification Standards

- ISO 9001 (quality management);

- ASTM C919 (acoustic seals);

- UL Fire Ratings (e.g., UL 2079 for joint systems).

Pricing Factors & Market Trends

Cost Drivers

- Raw Materials: EPDM ($2–4/kg), silicone rubber ($8–15/kg), FKM ($20–30/kg);

- Production Complexity: Custom profiles (+30–50% cost vs. standard extrusions);

- Certifications: Fire-rated seals (+20–40% premium for testing/compliance).

Price Ranges

| Product Type | Price Range (per meter) | Key Influencers |

|---|---|---|

| Standard EPDM seals | $0.50–$2.00 | Volume discounts, UV additives |

| Silicone glazing seals | $3.00–$8.00 | Food-grade compliance, high-temp stability |

| Fire-rated intumescent seals | $10–$25 | Fire endurance duration (1–4 hrs) |

Market Trends

- Growing demand for energy-efficient seals (CAGR 6.2% in green buildings);

- Shift toward hybrid materials (e.g., silicone-EPDM blends) to balance cost/performance;

- Automation in extrusion lines reduces labor costs by 15–25%.

Applications & Functional Integration

Building Envelope Systems

- Curtain Walls: Silicone glazing seals (UV resistance);

- Expansion Joints: Polyurethane seals for thermal movement.

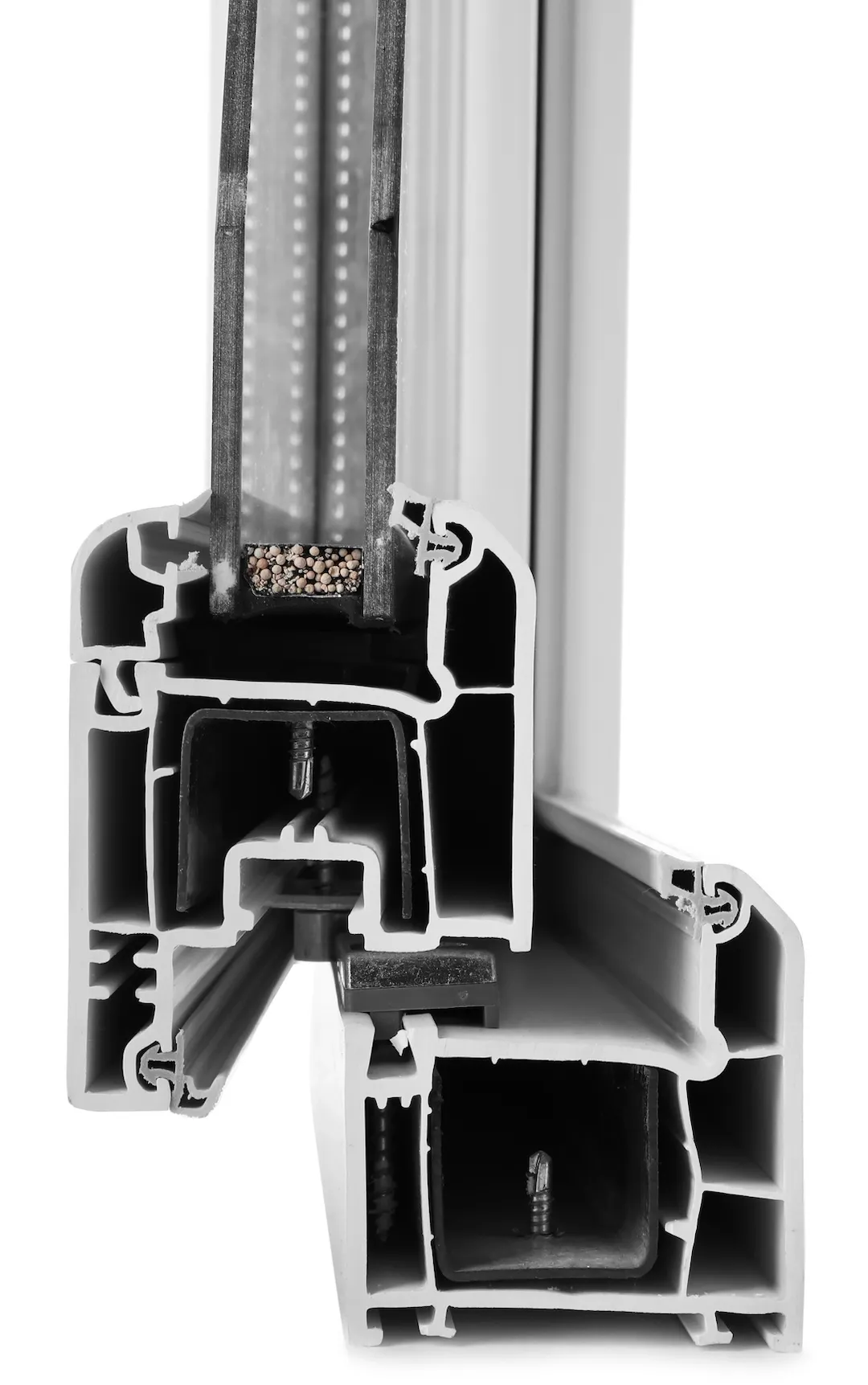

Window & Door Systems

- Frame Seals: EPDM gaskets (water/air infiltration prevention);

- Double Glazing: Silicone secondary seals (gas retention).

Specialized Scenarios

- Fire Protection: Intumescent seals (smoke blocking);

- Acoustic Insulation: Multi-chamber EPDM (30+ dB reduction);

- Seismic Adaptation: High-elasticity silicone (structural displacement absorption).

Key Performance Metrics

Mechanical Properties

- Compression Set: ≤20% stress relaxation under heat;

- Hardness (Shore A): 60–90 (balance of flexibility/durability).

Environmental Resistance

- Temperature Stability: TR10 (low-temperature retraction) & post-aging strength retention;

- Chemical Compatibility: ≤10% volume change after oil immersion.

Durability Testing

- UV Aging: ≥80% tensile strength retention after accelerated testing;

- Lifetime Prediction: Arrhenius model for thermal aging.

Energy Efficiency & Compliance

Energy-Saving Mechanisms

- Air Tightness: 15% HVAC energy reduction via 50% leakage control;

- Thermal Breaks: EPDM spacers (window U-value improvement).

Standards & Certifications

- China GB: GB/T 24498 (window/door seals), GB 16807 (fire-rated seals);

- Global: ASTM C919 (acoustic seals), EN 1366-4 (fire testing).

Testing Protocols

- Air Infiltration: Blower door tests (air changes per hour);

- Glazing Integrity: -40°C dew point tests for seal failure.

Advanced Functional Requirements

Fire-Rated Seals

- Materials: Graphite-expanding/certifiable silicone;

- Fire Resistance: 1–4 hours (GB 23864 classification).

Acoustic Optimization

- Design: Multi-chamber + high-density fillers;

- Performance: Dynamic stiffness ≤15 MN/m³.

Seismic Performance

- Movement Tolerance: ±25% joint width accommodation (silicone);

- Fatigue Resistance: 50,000 cycles without cracking.