Albang Hardware produces specialized fasteners made of stainless steel for architectural applications. These stainless steel fasteners, including screws, bolts, and nuts, are often employed in constructing buildings, bridges, and various structures. Favored for their exceptional strength, durability, and corrosion resistance, these fasteners are particularly suitable for outdoor and marine environments. Albang offers an extensive range, from standard items to custom-made fasteners tailored to specific architectural needs.

Table of Contents

What Are Architectural Stainless Steel Fasteners?

Definition and Overview

Architectural stainless steel fasteners are precision-engineered components used to securely join architectural elements. Their primary function is ensuring structural integrity and aesthetic appeal in construction projects.

Importance in Architectural Applications

These fasteners play a crucial role in maintaining the stability, longevity, and visual harmony of architectural designs, especially in challenging environments such as coastal regions and outdoor spaces.

Classification of Architectural Stainless Steel Fasteners

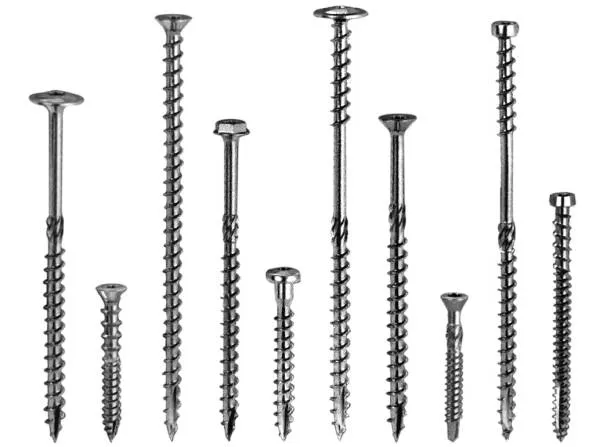

Screws

- Machine Screws

- Self-Tapping Screws

- Wood Screws

Bolts

- Hex Bolts

- Eye Bolts

- Carriage Bolts

Nuts

- Hex Nuts

- Lock Nuts

- Cap Nuts

Anchors

- Expansion Anchors

- Sleeve Anchors

- Concrete Anchors

Washers

- Flat Washers

- Lock Washers

- Spring Washers

Rivets

- Blind Rivets

- Solid Rivets

Pins

- Cotter Pins

- Dowel Pins

Popular Models and Specifications

Material Grades and Properties

- Stainless Steel 304

- Stainless Steel 316/316L

- Duplex Stainless Steel 2205

Standard Sizes and Dimensions

- Diameter and Length Standards

- Thread Types and Standards (Metric, UNC)

Surface Finishes

- Polished Finish

- Satin Finish

- Brushed Finish

- Mirror Finish

Purpose and Applications of Architectural Stainless Steel Fasteners

Indoor Applications

- Railings and Balustrades

- Fixtures and Decorative Elements

Outdoor Applications

- Facades and Cladding

- Structural Supports

Coastal and Marine Environments

- Corrosion-resistant Solutions

- Marine-grade Fasteners (316, Duplex 2205)

Manufacturing Process of Stainless Steel Fasteners

Material Selection and Preparation

Materials undergo rigorous selection to meet strict quality criteria, ensuring superior durability and corrosion resistance.

Forming and Threading Techniques

Advanced machining and threading techniques guarantee precise dimensions and reliable performance.

Surface Treatment and Finishing

Processes such as polishing, brushing, or satin finishing enhance appearance and resistance to corrosion.

Quality Control and Inspection Procedures

All products are subjected to stringent quality checks to ensure compliance with international standards.

Pricing and Cost Considerations

Factors Influencing Price

- Material Grade

- Size and Complexity

- Surface Finish and Treatment

Cost Comparison by Type and Application

- Economical Options

- Premium and High-performance Options

Customization Services for Architectural Stainless Steel Fasteners

Tailored Dimensions and Specifications

Albang provides custom dimensions to meet unique project specifications.

Custom Surface Finishing Options

Clients can choose specialized surface treatments to match aesthetic requirements.

Special Requirements for Specific Projects

Dedicated design support for demanding or unusual applications.

Standards, Compliance, and Certification

International Fastener Standards (ASTM, ISO, DIN)

All products comply with leading global standards ensuring reliability.

Importance of Standards Compliance

Compliance ensures fasteners meet structural safety and environmental durability requirements.

Certification and Documentation

Detailed certifications and documentation are provided with each product delivery.

Installation Methods and Best Practices

Threaded and Bolted Installation

Common and reliable method suitable for many architectural applications.

Anchor-based Installation

Ideal for heavy-duty structural fastening needs.

Welded Fastening Techniques

Suitable for permanent installations requiring high structural integrity.

Tools and Accessories for Installation

Proper installation tools are essential to achieving optimal results.

Maintenance and Care Recommendations

Routine Inspection and Maintenance Tips

Regular inspections to ensure integrity and longevity.

Handling Corrosion and Damage Prevention

Guidelines on preventive measures to prolong lifespan.

How to Select the Right Architectural Fastener for Your Project

Evaluating Environmental Conditions

Understanding the environmental exposure to choose appropriate materials.

Assessing Load and Strength Requirements

Selecting fasteners based on structural demands.

Matching Aesthetic Considerations

Ensuring fasteners align aesthetically with architectural design goals.

Why Choose Albang Hardware for Architectural Stainless Steel Fasteners?

Expertise and Industry Experience

Years of proven expertise in supplying high-quality fasteners.

Quality Assurance and Certifications

Unwavering commitment to quality and international standards.

Customization and Tailored Solutions

Offering tailored solutions precisely aligned with project specifications.

Conclusion

Albang Hardware specializes in providing durable, reliable, and aesthetically pleasing architectural stainless steel fasteners for diverse applications, from commercial to residential projects. Our commitment to excellence ensures that you receive the best products tailored to your specific architectural needs.

Contact Albang Hardware to discuss your project requirements and experience unparalleled quality and service in architectural stainless steel fasteners.