Albang Hardware is one of the earliest manufacturers of glass spider fittings in China, with more than 20 years of experience in glass curtain wall projects. We offer rapid design services within 24 hours, 3D prototyping samples within 72 hours, molds for spider fittings completed in 3 days, and bulk order delivery within 7-10 days.

Table of Contents

Introduction to Glass Spider Fittings

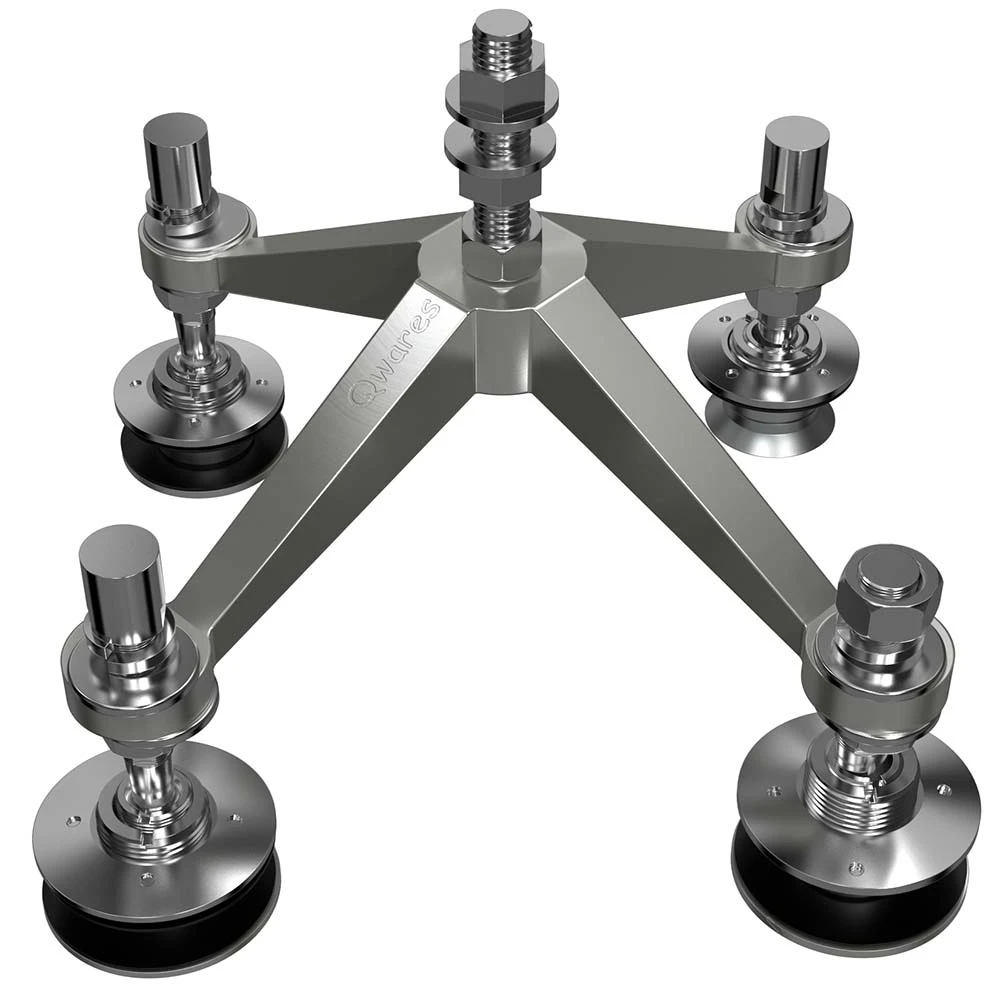

Glass spider fittings are modern architectural hardware components used to secure and support glass panels in various structural applications, offering transparency, strength, and aesthetic appeal. These fittings allow architects and designers to create sleek, elegant facades with minimal visual obstruction.

Classification of Glass Spider Fittings

By Number of Arms

- 1-Way Spider Fittings: Suitable for edge installations.

- 2-Way Spider Fittings: Ideal for linear glass structures.

- 3-Way Spider Fittings: Perfect for corner joints.

- 4-Way Spider Fittings: Commonly used in central installations.

- Custom Spider Fittings: Tailored designs based on project-specific requirements.

By Mounting Methods

- Wall-Mounted Spider Fittings

- Point-Fixed Spider Fittings

- Cable-Supported Spider Systems

By Surface Finishes

- Polished Finish

- Brushed Finish

- Satin Finish

- Powder-Coated (available in custom colors)

Glass spider fittings drawings free download

Albang Hardware offers free AutoCAD drawings for various models of glass spider fittings. Click the link below to download.

200mm glass spider fittings

210mm glass spider fittings

220mm glass spider fittings

250mm glass spider fittings

300mm glass spider fittings

250/400mm glass spider fittings

300/600mm glass spider fittings

spider connector

Applications of Glass Spider Fittings

Curtain Walls

Provides structural support and visual transparency. Price range: $15 – $50 per unit.

Facade Systems

Enhances structural stability and aesthetics. Price range: $20 – $60 per unit.

Glass Canopies

Ideal for weather protection and architectural elegance. Price range: $20 – $80 per unit.

Railings and Balustrades

Ensures safety with minimal visual interference. Price range: $30 – $90 per unit.

Manufacturing Process of Glass Spider Fittings

Material Selection

Premium stainless steel (Grade 304 or 316) and aluminum alloys for lightweight solutions.

Fabrication Techniques

Utilizing precision investment casting and CNC machining to ensure accurate dimensions and optimal quality. Final finishes include polishing, brushing, and powder coating.

Quality Control & Testing

Rigorous load testing, corrosion resistance checks, and precise dimensional inspections guarantee reliability.

Reference Pricing Guide for Glass Spider Fittings

Pricing is influenced by material quality, complexity of design, finishes, and quantity. Standard fittings range from $10 (single-arm) to $80 (complex 4-arm or custom).

Customization Services Offered

Albang Hardware provides extensive customization options including:

- Custom arm configurations

- Special surface finishes

- Branding and engraving

- Customized packaging

- Technical consultation and design assistance

Installation Methods and Guidance

Typical Installation Methods

- Point-Fixed Installation: Involves securing spider fittings directly to glass panels through drilled holes. Precise measurements and careful alignment are crucial.

- Cable-Supported Installation: Utilizes tensioned cables to support spider fittings, ideal for lightweight and visually appealing installations.

- Wall-Mounted Installation: Attaching fittings to structural walls, providing a robust and secure anchorage method suitable for heavier glass panels.

Required Tools & Equipment

Professional tools such as glass drilling equipment, torque wrenches, measurement instruments, and personal protective gear.

Compliance with Standards and Regulations

All fittings adhere strictly to International Building Codes (IBC), ASTM standards, and local safety regulations ensuring compliance and safety.

Featured Project Case Studies

- Commercial Building Facade: Modern glass installation, New York, USA.

- Airport Terminal Canopy: Large-scale project, Tokyo, Japan.

- Office Complex Curtain Wall: Structural elegance, Berlin, Germany.

Selecting a Reliable Glass Spider Fitting Manufacturer

Criteria for Manufacturer Selection

Prioritize experience, certifications, customer testimonials, and customization capabilities when selecting your supplier.

Recommended Manufacturers & Suppliers

- Albang Hardware (China): Specializes in stainless steel fittings, provides comprehensive technical support and customization.

- Leading European and American providers offering premium or rapid-delivery options.

Maintenance and Care Instructions

Regular cleaning, safety inspections, and timely replacements extend the life of spider fittings and ensure ongoing structural integrity.

People ask Ask

What glass thicknesses are compatible?

The range of glass thicknesses that can safely and effectively be used with glass spider fittings. Generally, compatible glass thicknesses range from 8mm to 25mm, depending on the application, spider fitting type, and load requirements. For most common structural installations, thicknesses of 10mm, 12mm, 15mm, and 19mm are frequently used. It’s essential to verify with specific manufacturer recommendations or consult directly with Albang Hardware for exact project guidelines.

Are glass spider fittings suitable for seismic areas?

Yes, glass spider fittings are suitable for seismic areas when properly designed and installed. Albang Hardware’s fittings are engineered with flexibility and strength to accommodate building movements and seismic vibrations. Special considerations include using flexible connection points, appropriate glass thickness, and professional seismic analysis during the design phase to ensure safety and compliance with seismic building codes.

How to calculate load-bearing capacities of glass spider fittings?

Calculating load-bearing capacities involves evaluating several factors, including glass thickness, fitting type, installation method, glass panel dimensions, and expected environmental conditions (wind load, snow load, etc.). Typically, structural engineers conduct detailed calculations using industry-standard software tools or manual methods based on applicable building codes and ASTM guidelines. Albang Hardware offers professional technical support to assist with precise load-bearing calculations for your specific project requirements.

Conclusion

Albang Hardware’s glass spider fittings provide strength, elegance, and reliability for modern architectural projects. Leverage our expertise to ensure your project’s success.

Contact Albang Hardware today for expert advice, detailed quotations, and customized glass spider fitting solutions tailored precisely to your project’s needs.